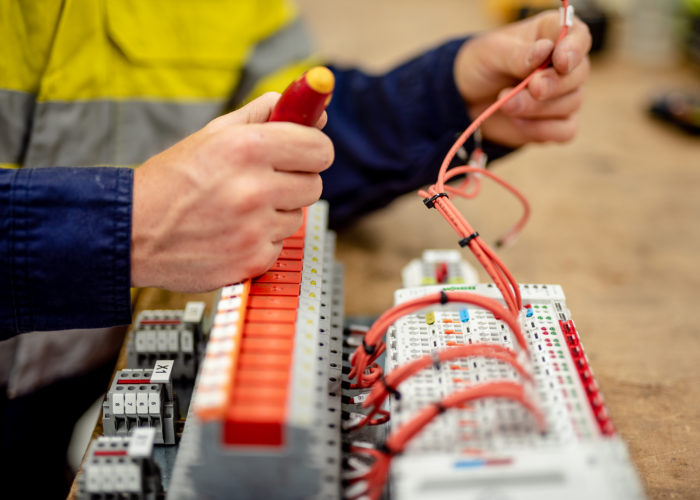

Cutting edge Automation and Control technology for Hazardous Areas

Cutting edge Automation and Control technology in Hazardous Areas. Handling the data and information to operate plants and equipment:

- Intrinsically Safe Barriers, Relays and Isolators

- Remote I/O Control Units

- Ground/Earth Monitoring Systems

- Ex p Pressurised Systems

- Optical Fibre splicing

- Wireless and Data systems

The technology used to run modern production facilities doesn’t need to stop at the Hazardous Area, but it will require some thought and flexibility. We can assist with any custom solutions, mixing Ex protected equipment and mainstream industrial equipment to help customers operate efficiently. Calculating and connecting Intrinsically safe devices, multiple data-transfer methods, or including bespoke designs and equipment.

We have the engineering and consulting capacity to determine and provide the right equipment for your operations. We are also able to assist with changes to IP-based communication with Wireless LAN, IP CCTV, Bluetooth-tracking and smart devices.

IECEx Certified

Workshop

Our purpose-built workshop in Perth has been certified to repair the following types of protection: Ex t, Ex d, Ex e, Ex n and Ex i. This means that all of our customised, designed, repaired and assembled Ex rated equipment is guaranteed to be compliant.

Engineering Capability

EX Engineering differ from most Hazardous area electrical suppliers in we have the capability and competency to select and review products through our engineering team. We have electrical engineers with the competency to:

- Review and classify hazardous areas,

- Select equipment suitable for use in a hazardous area

- Complete the required engineering calculations to demonstrate compliance (such as MDP, IS Parameters etc…)

- Have an in depth understanding of protection techniques.

- Review and give opinion on equipment suitability.

- Create and issue Conformity Assessment Documents (CAD)

- Create bespoke EX Solutions.

- Issue repair certification for equipment repaired in our workshop.

Hazardous area’s is all that we do, and we don’t just sell hazardous area certified products we manufacture, repair and certify them.

Quality Assurance

We have a structured Quality Assurance (QA) system, that allows us to pay more attention than is required.

Depending on how critical the shipment is, we assign a QA level that determines whether the product is checked by one person, two people, or the engineering team – so the QA is always tailored to suit.

Our process involves two different check levels that ensure;

- Overall compliance

- The product is fit for purpose

About EX Engineering

EX Engineering is a family business specialising in the supply and design of hazardous area electrical equipment. EX Engineering is committed to supporting our customers with reliable advice, guidance and products to ensure their projects are compliant, completed on time with safety as the main priority.

Since 2013 our team of experienced and knowledgeable staff have been delivering the best solutions to meet hazardous area requirements across many industries, including Oil & Gas, Manufacturing, Agriculture and LNG.

95

1

100,000

Contact Our Team Today.

Whether you need help sourcing, repairing or customising a product, or just would like some guidance in navigating hazardous areas, we are happy to help.

We will get back to you in lightning speed.